A plane is a tool for shaping wood. Planes are used to flatten, reduce the thickness of, and impart a smooth surface to a rough piece of lumber. Planing is used to produce horizontal, vertical, or inclined flat surfaces on workpieces usually too large for shaping. Special types of planes are designed to cut joints or decorative mouldings.

Hand planes are generally the combination of a cutting edge, such as a sharpened metal plate, attached to a firm body, that when moved over a wood surface, take up relatively uniform shavings, by nature of the body riding on the 'high spots' in the wood, and also by providing a relatively constant angle to the cutting edge, render the planed surface very smooth. A cutter which extends below the bottom surface, or sole, of the plane slices off shavings of wood. A large, flat sole on a plane guides the cutter to remove only the highest parts of an imperfect surface, until, after several passes, the surface is flat and smooth.

Though most planes are pushed across a piece of wood, holding it with one or both hands, Japanese planes are pulled toward the body, not pushed away.

Woodworking machinery that perform the same function as hand planes include the jointer and the thickness planer, also called a thicknesser.

History and development of the hand plane

Hand planes are ancient, originating thousands of years ago. Early planes were made from wood with a rectangular slot or mortise cut across the center of the body. The cutting blade or iron was held in place with a wooden wedge. The wedge was tapped into the mortise and adjusted with a small mallet, a piece of scrap wood or with the heel of the users hand. Planes of this type have been found in excavations of old sites as well as drawings of woodworking from medieval Europe and Asia. Roman planes found at Pompeii are largely similar to planes in use today. In fact wooden planes can still be bought from modern plane makers.

In the mid 1860's, Leonard Bailey began producing a line of cast iron-bodied hand planes, the patents for which were later purchased by Stanley Rule & Lever, now Stanley Works. The original Bailey designs were further evolved and added to by Justus Traut and others at Stanley Rule & Lever. The Bailey and Bedrock designs became the basis for most modern metal hand plane designs manufactured today. The Bailey design is still manufactured by Stanley Works.

Modern hand planes are made from wood, cast iron or even bronze.

Parts of a plane

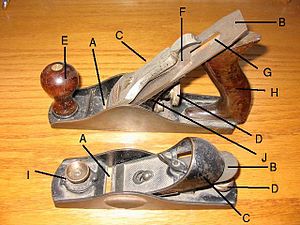

Two styles of plane are shown with some parts labeled. The top of the image is a bench plane; the bottom is a block plane.

- A: The mouth is an opening in the bottom of the plane down through which the blade extends, and up through which wood shavings pass.

- B: The iron is a plate of steel with a sharpened edge which cuts the wood. Some people refer to it as the blade.

- C: The lever cap holds the blade down firmly to the body of the plane.

- D: The depth adjustment knob controls how far the blade extends through the mouth.

- E: The knob is a handle on the front of the plane.

- F: The chipbreaker or Cap iron serves to make the blade more rigid and to curl and break apart wood shavings as they pass through the mouth.

- G: The lateral adjustment lever is used to adjust the iron by skewing it so that the depth of cut is uniform across the mouth.

- H: The tote is a handle on the rear of the plane.

- I: The finger rest knob Block planes are held in the palm of the hand the tip of the user's index finger rests in the indentation on top of the knob. On some planes the knob is used to adjust the size of the mouth by allowing a sliding portion of the sole to be moved back or forward to accomplish this.

- J: The frog is a sliding iron wedge that holds the plane Iron at the proper angle. It slides to adjust the gap between the cutting edge and the front of the mouth. The frog is screwed down to the inside of the sole through two parallel slots and on many planes is only adjustable with a screwdriver when the plane iron is removed. Some planes, such as the Stanley Bedrock line and the bench planes made by Lie-Nielsen have a screw mechanism that allows the frog to be adjusted without removing the blade.

Types of planes

Most planes are categorized as either bench planes or block planes. In modern-day carpentry, electrically powered hand planers (also called hand or handheld power planers or simply power planes) have joined the family.

Bench planes are characterized by the cutting iron bedded with the bevel facing down and attached to a chipbreaker. Block planes are characterized by the absence of a chipbreaker and the cutting iron bedded with the bevel up. The block plane is usually a smaller tool that can be held with one hand and is used for general purpose work such as taking down a knot in the wood, smoothing up small pieces, making the end of a sawed board square and smooth.

Different types of bench planes are designed to perform different tasks, with the name and size of the plane being defined by the use. They are designed to be used in order:

- A scrub plane, which removes large amounts of wood quickly, is typically around 9 inches (230 mm) in length, but narrower than a smoothing plane, and has an iron with a curved cutting edge.

- A jack plane is around 14 inches (350 mm) long, continues the job of roughing out, but with more accuracy than the scrub.

- A jointer plane (including the smaller fore plane) is between 18 to 24 inches (450-600 mm) long, and is used for jointing and final flattening out of boards.

- A smoothing plane, up to 10 inches (250 mm) long, is used to begin preparing the surface for finishing.

Planes may also be classified by the material of which they are constructed:

- A wooden plane is entirely wood except for the blade. The iron is held into the plane with a wooden wedge, and is adjusted by striking the plane with a hammer.

- A transitional plane has a wooden body with a metal casting set in it to hold and adjust the blade.

- A metal plane is largely constructed of metal, except, perhaps, for the handles.

- An infill plane has a body of metal filled with very dense and hard wood on which the blade rests and the handles are formed. They are typically of English or Scottish manufacture. They are prized for their ability to smooth difficult grained woods when set very finely.

Some special types of planes include:

- The spokeshave, which has a very short sole, either flat or curved, and is used for smoothing curved surfaces.

- The shoulder plane, is characterized by a cutter that is flush with the edges of the plane, allowing trimming right up to the edge of a workpiece. It is commonly used to clean up dadoes (housings) and tenons for joinery.

- The moulding plane, which is used to cut mouldings along the edge of a board

- The rabbet plane, also known as a rebate or openside plane, which cuts rabbets (rebates) i.e. shoulders, or steps.

- The plow plane, which cuts grooves and dadoes (housings).

- The router plane, which cleans up the bottom of recesses such as shallow mortises and dadoes (housings).

- The chisel plane, which removes wood up to a perpendicular surface such as from the bottom inside of a box.

- The finger plane, which is used for smoothing very small pieces such as toy parts, very thin strips of wood, etc. The very small curved bottom variates are known as violin makers planes and are used in making stringed instruments.

- The bullnose plane has a very short leading edge to its body, and so can be used in tight spaces; most commonly of the shoulder and rabbet variety.

- The combination plane, which combines the function of a moulding and rabbet planes, having different cutters and adjustments

- The circular or compass plane, which utilizes an adjustment system to control the flex on a steel sheet sole and create a uniform curve. A concave setting permits great control for planing large curves, like table sides or chair arms, and the convex works well for chair arms, legs and backs, and other applications.

Tidak ada komentar:

Posting Komentar